We design molded plastics that help ensure roadway caution and safety, as well as several forms of medical housings.

Crash guard plastic barrels are built to prevent fatal car accidents. Although crashes are inevitable at times, we want to ensure that cars and drivers do not crash into concrete medians or barriers. Crash guard barrels are set up so cars can hit them instead of the medians and barriers. Barrels absorb some of the impact, which helps protect the drivers and passengers in the vehicle and lessen the damage.

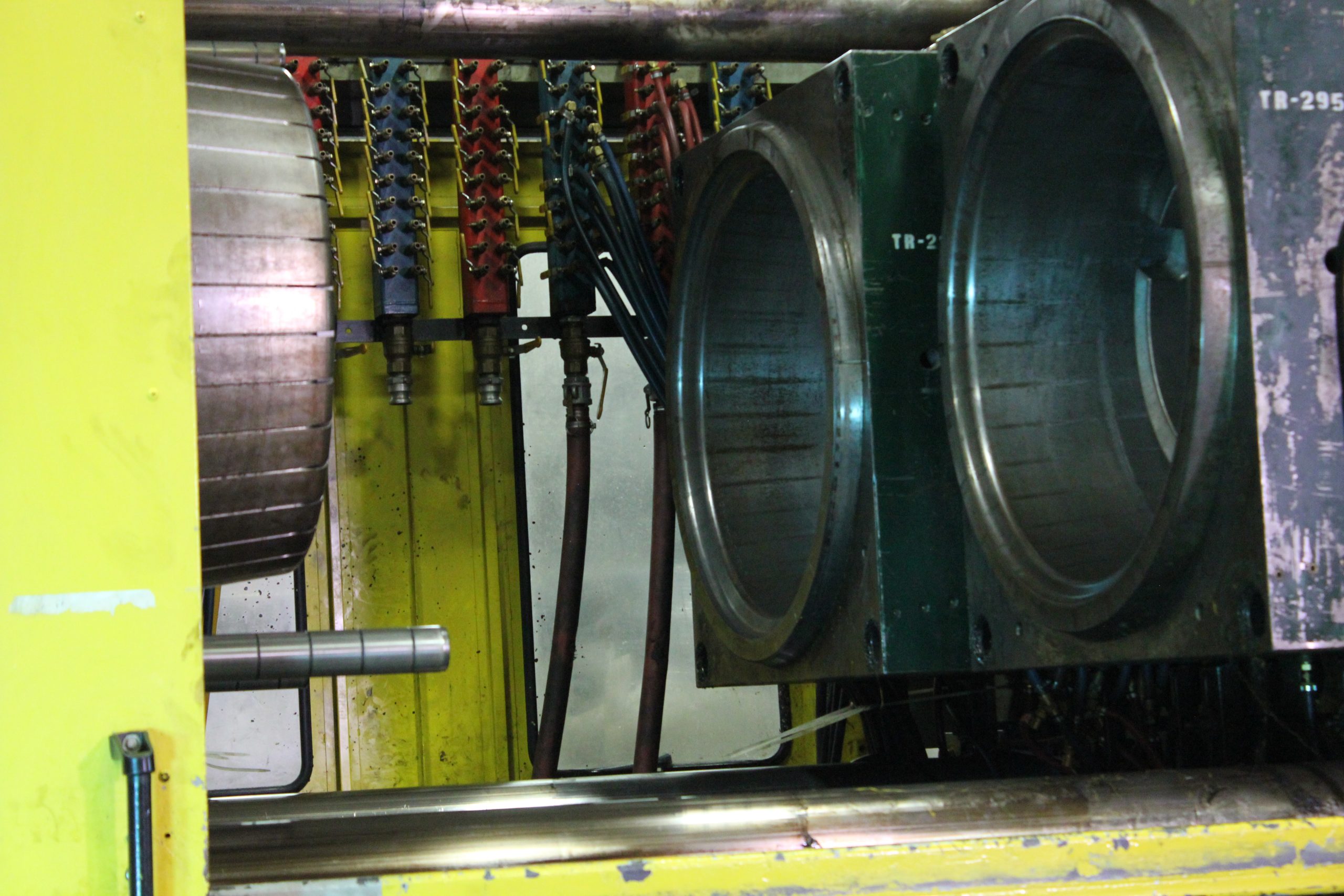

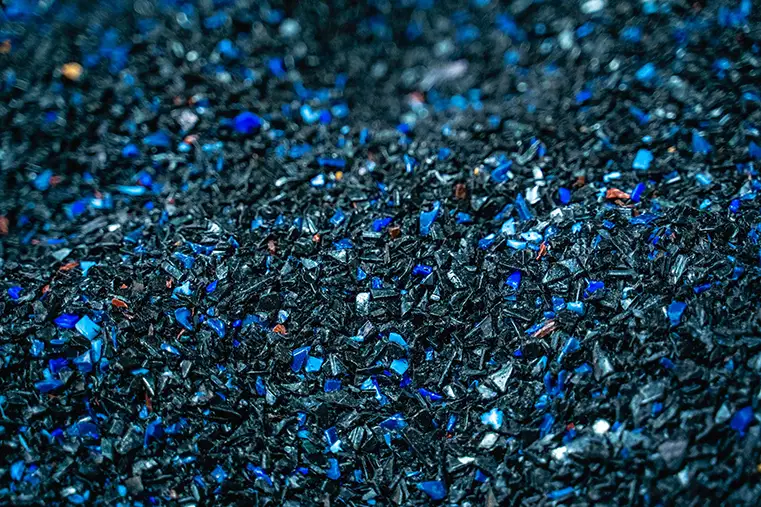

DeKALB designs and manufactures plastic guard rail cross sections to increase the strength and durability of metal guard rails that line the edge of high drop-off areas and other congested places. If a vehicle crashes into a guard rail, the hope is that the guard rail will be strong enough to withstand the crash’s impact, help keep the car on the road, and reduce the risk of flipping or hitting immobile objects. DeKALB manufactures the plastic cross sections for these guard rails with our foam injection molding process, allowing these pieces to be as durable as possible to withstand the impact of a car crash.

DeKALB Molded Plastics hopes to increase roadway safety by making our safety products and devices better, stronger, and longer lasting than past products. We want to continue to research newer and better technologies to make the road safer for us and safer for our children, who will one day be driving on their own.

DeKALB consistently designs innovative products with our multi-point foam injection process. Our product range includes:

- Plastic pallets

- Dialysis plastic enclosure cabinet

- Bone densitometer plastic enclosure cabinet

- Electric med bed housing

- Plastic traffic barrels

- Plastic guardrail blocks