Engineering Services

- Complete part design review

- C.A.D. Finite Element Analysis (FEA)

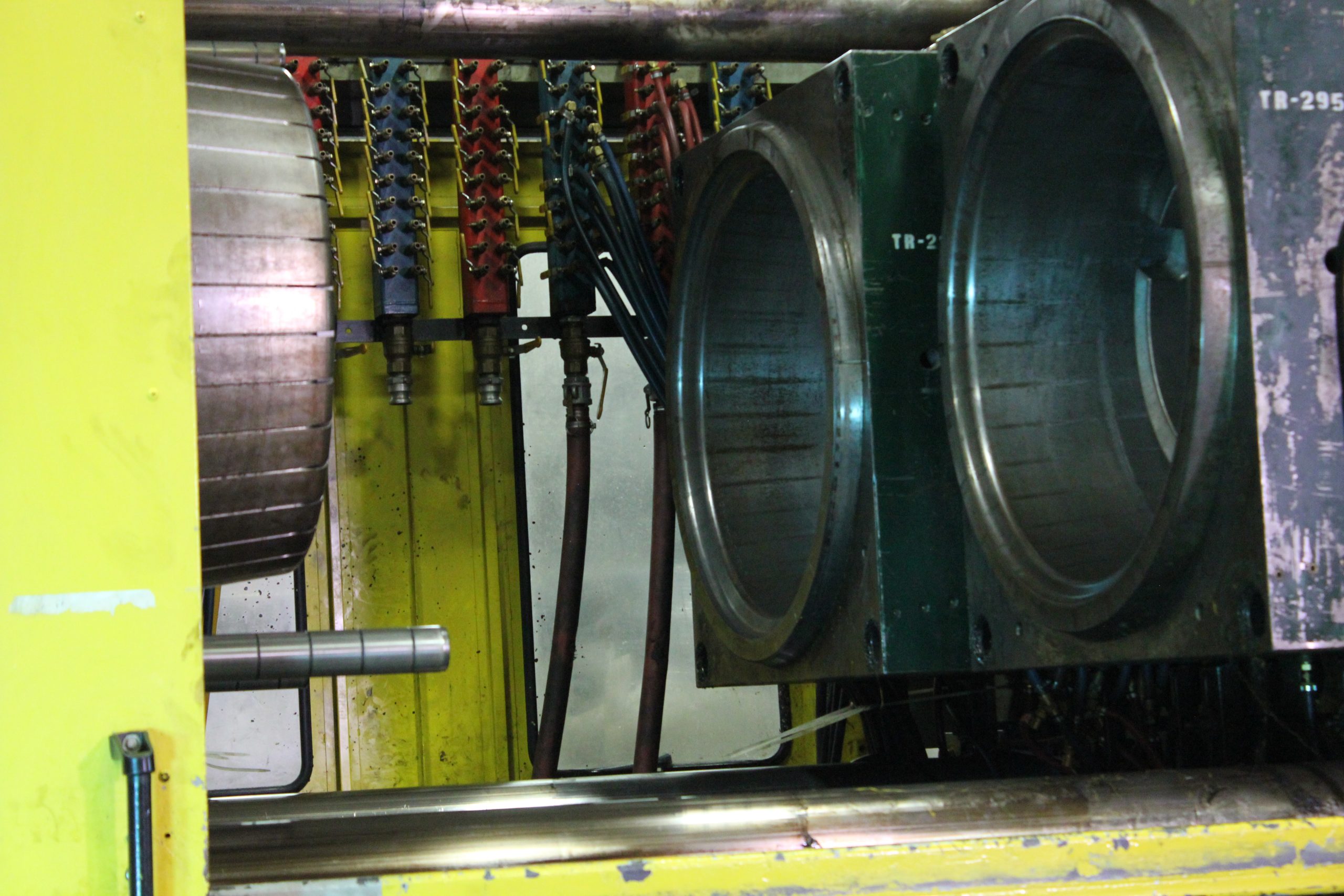

- Mold flow / Mold cool

- Project optimization

- Project management

- Plastics tool design and build management

- Material selection

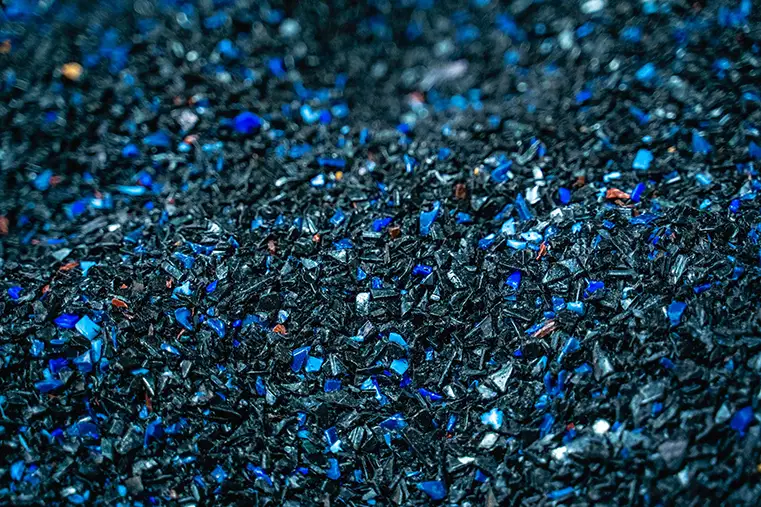

Alternative Materials Conversion

Fiberglass

While fiberglass parts may serve well as prototypes, the structural foam molding process has many advantages: shorter cycle times than RTM or hand layup and greater consistency of mounting points, to name a few. Structural foam also provides a better fit for mating components, preventing catalysts from blooming out of the part and VOC production issues.

Metal

Although sheet metal has historically been an alternative to plastics, there are several areas where plastics can perform equally and at a lower price point. Multiple-part integration is just one example of the robust solutions available with plastics. Structural foam plastic parts can also be recycled at the plant of origin, proving it to be a superior process for producing your part.