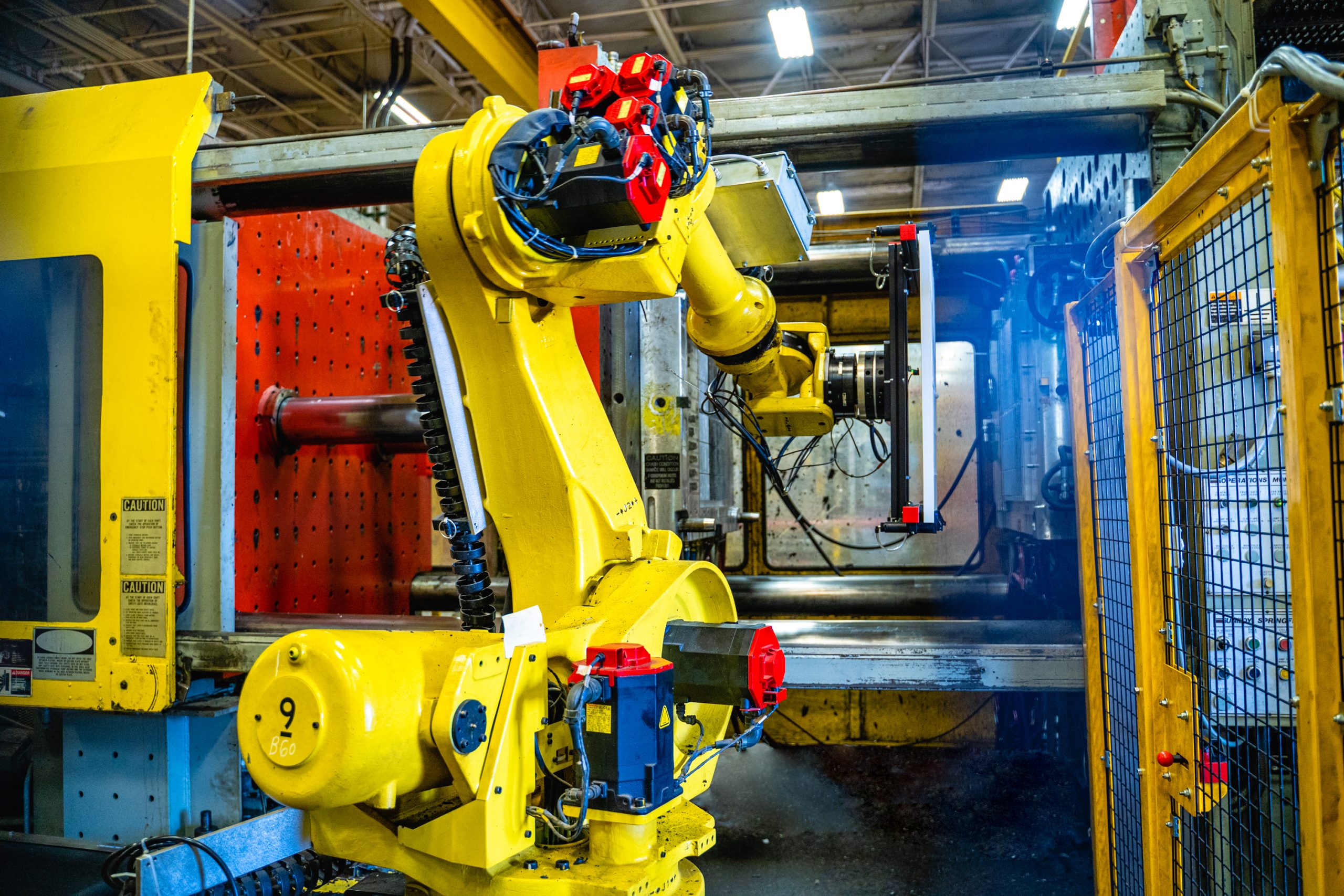

Structural Foam Molding Services

At DeKALB Molded Plastics, the push for high-quality processes inspires us to think outside the box and manufacture custom molding solutions. Since 1978, our team has collaborated through team leadership, hands-on experiences, design support for structural plastics, and full-concept project management to develop molded products that exceed customer expectations. We work alongside customers to choose the best process for their project, including structural foam molding and gas assist injection molding. With strong internal resources and innovative ideas, our experienced team takes on the challenge of delivering turn-key product solutions.

What is Structural Foam?

The structural foam molding process offers a cost-effective alternative to standard injection molding practices while replacing common household products using materials like wood, metal, concrete, and fiberglass. This process reduces overall cost, material weight, and production time, leaving a quality finish trusted by many satisfied customers.

How Does it Work?

The foam molding process utilizes a foaming agent mixed with a base resin polymer melt before entering the injection mold. Once the mold is filled, the mixture becomes a combined polymer/gas melt. The foamed plastic mixture then goes through the mold, and the surface cells burst to create a solid skin that forms against the mold walls, creating a cellular structure.

Once production is complete, the result is a material 20% lighter and three to four times more rigid than solid plastic, produced with less molded-in stresses. This low-pressure molding procedure has less volume, opting for a partial fill method, unlike traditional injection molding practices that completely fill the mold. DeKALB’s cost-effective tooling solutions utilize large or multi-cavity molded products with larger sizes or multiple parts to be produced in a single machine and cycle.

NEED MORE INFO? CONTACT OUR TEAM!