Cost-Effective

Molding Solutions

Gas assist molding creates an alternative solution to other molding processes that is cost-effective and has a faster cycle time while reducing the overall weight. This process provides unique cosmetic finishes, such as low warps and no sink marks. With these features, the product receives flexibility and durability to work with larger plastic parts such as door handles, machine covers, and additional products with complex features – accounting for all the intricate details.

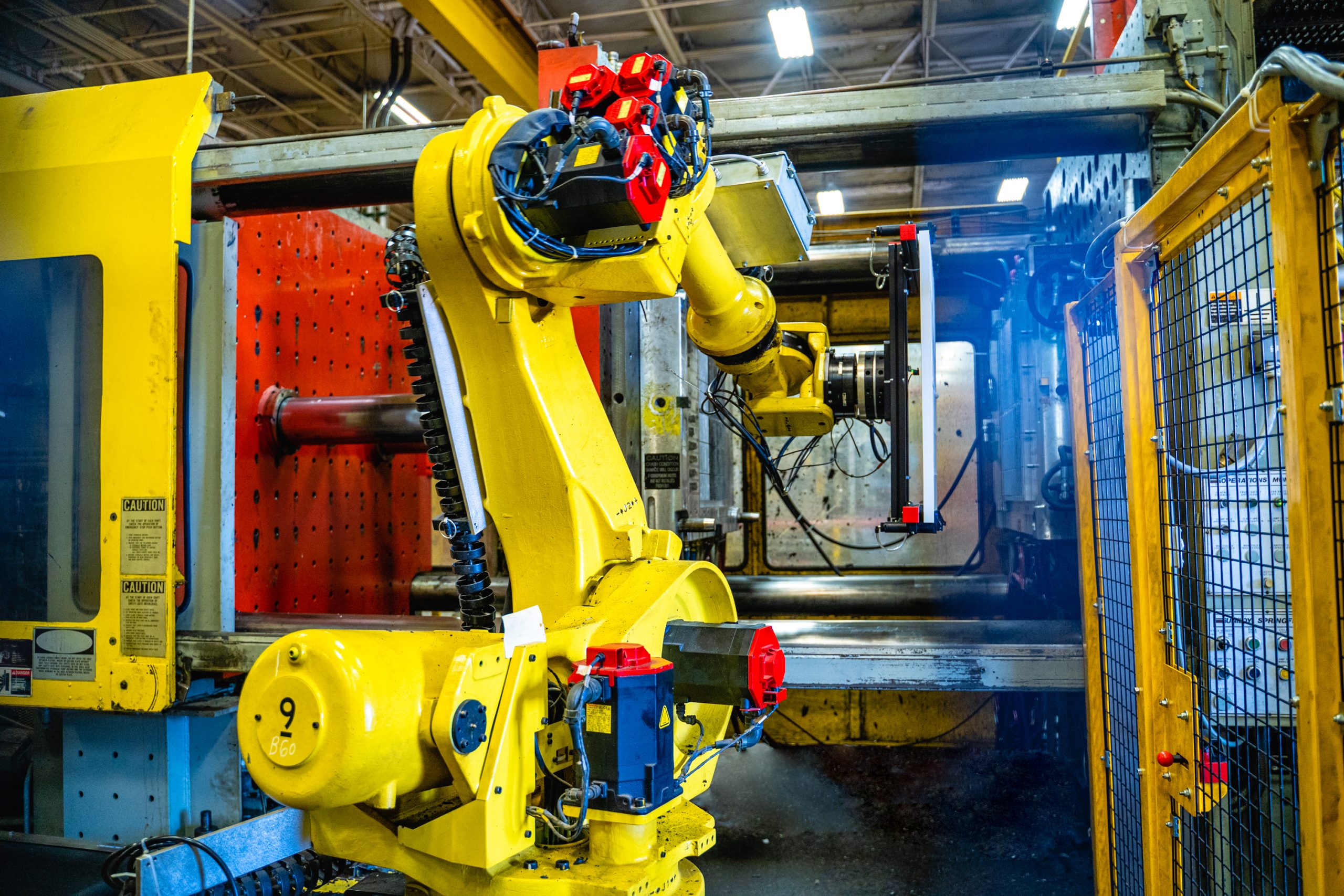

DeKALB utilizes Uniloy Springfield Structural Web Gas Assist and Bauer Gas Assist technologies in our process. The procedure begins with low-pressure injection molding using a partial fill method of resin that disperses nitrogen gas to fill and pack the remaining parts of the mold.

During the fill time, the resin and gas do not mix, forming channels through hotter and more viscous sections of the melt stream by displacing the polymers into thicker areas. When the walls are built, the gas maintains internal pressure throughout the cooling process, leaving the thicker wall sections with a sleek look with no marks, as with structural foam plastics.

Benefits of Gas Assist Molding:

- Design flexibility utilizing thick and thin wall sections

- Hollow gas channels increase stiffness and reduce the cooling time

- Improved aesthetics (low warp, no sink marks, etc.)

- Reduced cavity pressure equaling lower tonnage, more efficient machines

- Significantly reduced cooling and overall cycle time