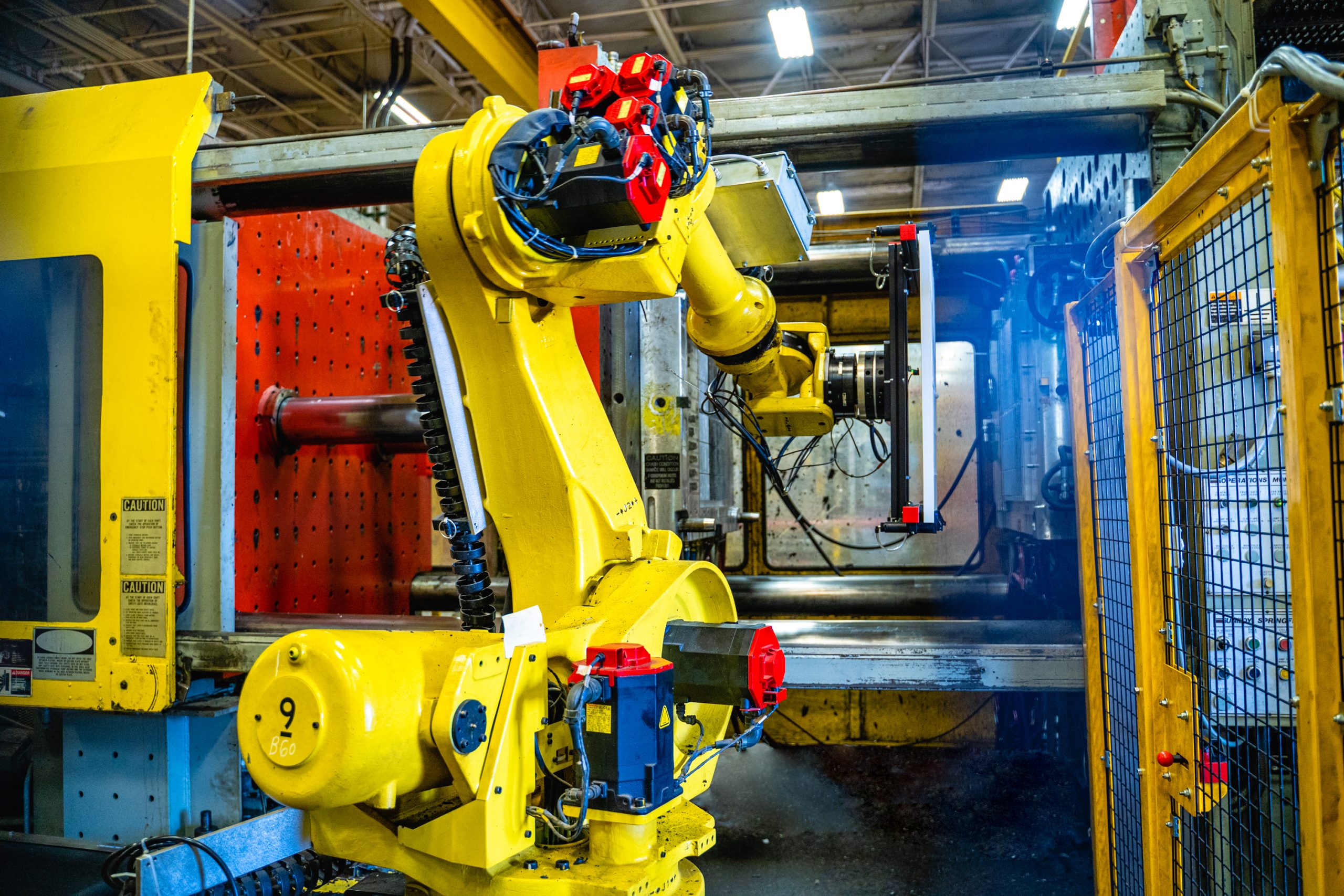

Structural Foam Molding

At DeKALB Molded Plastics, the push for high-quality processes inspires us to think outside the box and manufacture custom structural foam injection molding solutions. Since 1978, our team has collaborated through team leadership, hands-on experiences, design support assistance, and full concept project management to develop a product that exceeds customer expectations. We work alongside customers to choose the best process for their project, including structural foam molding and gas assist molding. With strong internal resources and innovative ideas, our experienced team takes on the challenge of delivering turn-key product solutions.

HAVE A PROJECT IN MIND? CONTACT OUR TEAM!

Before injection into the tool, inert gas is introduced into the melt.

Before injection into the tool, inert gas is introduced into the melt. Only a partial shot is used because, along with the low machine pressure, the gas creates a foaming action that helps the flow, fill, and pack of the mold.

Only a partial shot is used because, along with the low machine pressure, the gas creates a foaming action that helps the flow, fill, and pack of the mold.

Once the mold is completely packed out and begins to cool the ‘frozen’ outer skin becomes solid and rigid. The inner core develops a cellular or honeycomb structure when cooled.

Once the mold is completely packed out and begins to cool the ‘frozen’ outer skin becomes solid and rigid. The inner core develops a cellular or honeycomb structure when cooled.